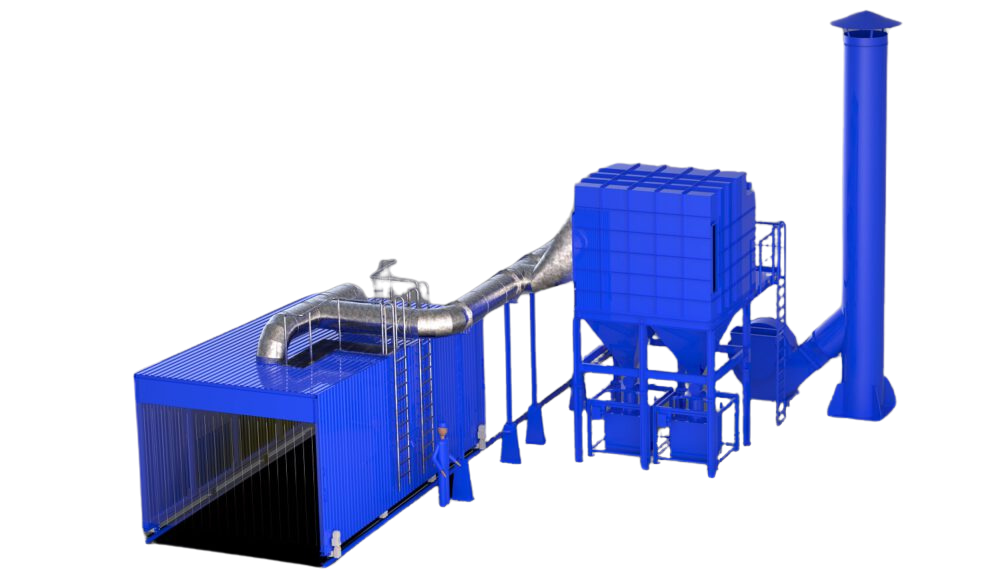

Mobile and stationary flame cutting extraction halls

Large, bulky machine parts or structures that cannot be pressed and sheared in scrap shears, need to be flame cutted with fuel gases such as propane or acetylene and oxygen.

This cutting process produces large amounts of flue gases containing iron, iron oxide and trace amounts of hydrocarbon compounds, which generate yellow to ocher smoke clouds.

The new EU air emission restrictions will bring various changes for operators of scrap processing plants from August 2022. Among other things, the new technical instructions for air require that the resulting exhaust gases and smoke clouds be intercepted and filtered when flame cutting metals with cutting lances. Based on the know-how of the Oberländer company with exhaust air purification systems, movable hoods for bulk boxes, and crane systems from the manufacturer DEMAG, it has been decided to offer solutions for this in the future that represent a cost-effective alternative to the large systems available on the market for smaller to medium-sized places.

For further information on this current topic, please contact us.

Complete roll-off container loads can be deposited and then shredded with flame cutting lances after driving over the hall.