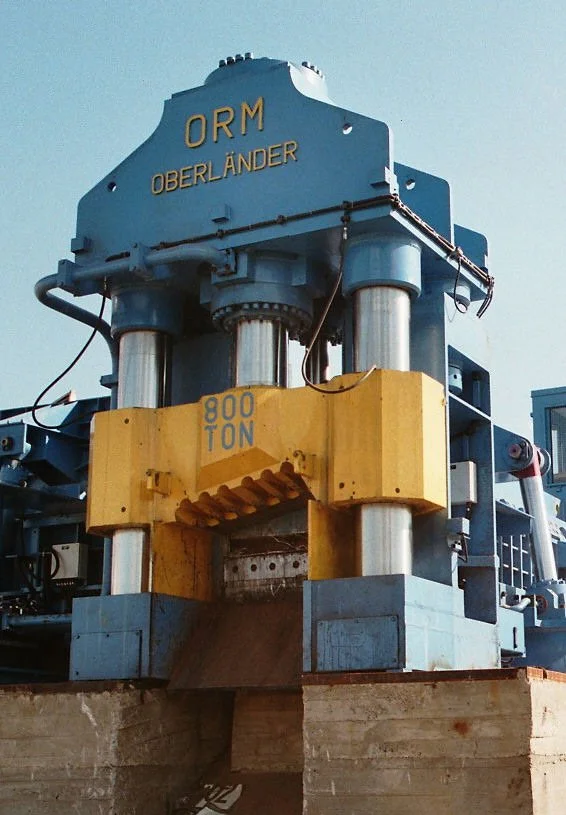

Stationary press shears

The hydraulic ORM scrap shears are the Oberländer basic concept, which has been tried and tested for more than 50 years, with cylindrical guidance of the knife slide, which ensures precise compliance with the cutting tolerance between the upper and lower knives. It is not necessary to adjust the guides. The scrap shears are made of a torsion-resistant welded construction; which enables installation without anchoring to the foundation and correspondingly low foundation costs.

What's new:

- Possibility of dismantling the shear and hold-down cylinders without dismantling the shear head;

- short pressing and shearing cycles thanks to improved hydraulic control;

- low power consumption thanks to power-controlled double pumps with controlled pivoting to a low delivery volume when idling;

- generous hydraulic pipe diameters and improved pipe routing with fewer bends to reduce pressure losses and produce less waste heat;

- comfortable steering chair in an air-conditioned control cabin for controlling the scissors;

- central oil and grease lubrication with large-volume storage containers and good accessibility to minimize and simplify maintenance intervals;

With the help of a hydraulically operated pre-filling trough, loading with scrap is possible while the shear is producing. This results in a significant reduction in loading time and a significant increase in production.

The mechanically processed press box enables the compressors to move precisely and the material to be pre-compacted quickly and without jamming.

Large-volume scrap is compacted effectively and easily with the help of the side compressor and a powerful press cover that extends over approx. 2/3 of the filling chamber width. The particularly long hold-down guides allow the scrap pre-pressed by the side compressor to be moved against the lowered hold-down device, so that packages can also be ejected with the scissors.

Generously dimensioned hydraulic pipe and valve cross sections allow for high hydraulic efficiency and low turbulence losses.

| PS 700 | PS 950 | PS 1100 | PS 1400 | PS 1700 | |

|---|---|---|---|---|---|

| Shear force [t] | 700 | 950 | 1.100 | 1.400 | 1.700 |

| Press box length [mm] | 6.000 | 7.000 | 7.000 | 8.000 | 8.000 |

| Press box width [mm] | 2.000 | 2.350 | 2.350 | 2.500 | 2.500 |

| Side compressor height [mm] | 600 | 800 | 800 | 800 | 1.000 |

| Cutting width [mm] | 710 | 950 | 950 | 1.250 | 1.450 |

| Strokes per minute approx. | 4 - 5 | 3 - 4 | 3 - 4 | 3 - 4 | 3 - 4 |

| Hold-down force [kN] | 170 | 3.350 | 4.180 | 5,560 | 6.870 |

| Cover force [kN] | 1x 2.470 | 2x 1.710 | 2x 1.710 | 4x 1.710 | 4x 2.470 |

| Side compressor force [kN] | 1x 2.470 | 2x 2.470 | 2x 3.360 | 2x 3.360 | 2x 4.840 |

| Feed force [kN] | 1.250 | 1.250 | 1.250 | 1.710 | 2.470 |

| Cutting performance [t/hour]* | 15 - 20 | 25 - 35 | 28 - 40 | 32 - 45 | 35 - 50 |

| Main drive [kW] | 2x75 | 3 / 4x90 | 4 / 5x90 | 5 / 6x90 | 6/7/8x90 |

| Total weight [t] | 130 | 220 | 250 | 350 | 450 |

| * depends on scrap type and cutting length | |||||